Products

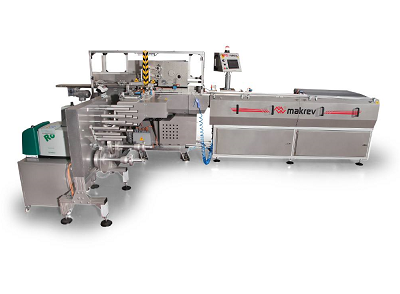

TWM350

General Information

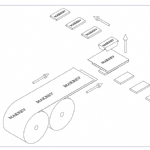

Packaging Shapes

:

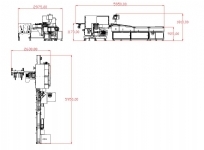

Product Dimensions

:

| MIN (mm) |

MAX (mm) | |

| Width | 25 | 85 |

| Length | 80 | 170 |

| Height | 6 |

20 |

1019039193618.JPG_1111126_buyuk17145351631675.JPG_1411412_K.jpg)

Wrapping Machine for Big Chocolate Tablets and Bars

Output: 220 pcs/min.(depending on the shape, dimensions of the product and wrapping material.)

• Several products with different dimensions can be wrapped (rectangular, square or bar)

• Wrapping application with 2 different variations;

· Two-layered wrapping (inner aluminium foil or wax paper - outer glossy/coated paper)

· Single-layered wrapping (aluminium foil, wax paper or glossy/coated paper)

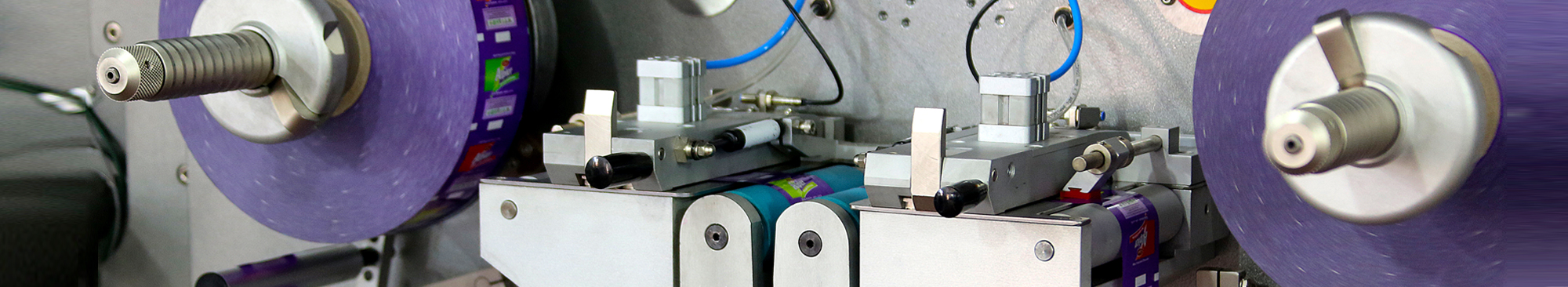

• Inner wrapping material is aluminum foil: 14-16 microns and outer wrapping material is glossy/coated paper: 60-80 gr/m²

• Photocell system for paper and products

• Servo motor driven wrapping material feeding

• Electronical parts used on the machine are branded OMRON, Schneider and SICK

• Pneumatic parts used on the machine are branded FESTO

• True-running radial cams with a hardened process for smooth operation and long durability

• Sequenced aligner and automatic feeding conveyors are suitable for the machine

• Delaying system for inner wrapping material

• Reject device for defective products

• Complete lubrication system

• Full machine control by HMI with color graphic touch screen

• All errors / warnings are visible on the touch screen

• The machine has a motion controller, and it is supported by 10 individual motor (inverter) groups

• Format or style changeover time is 30 minutes

• All format parts are manufactured exclusively for each product. Therefore, the machine does not require any further adjustments after the changeover

• CE certification

• Maintenance is easy for all operators

• Easily accessible parts

• Meets all hygienic requirements

• Automatic feeding conveyor (OPTIONAL)

• (Robatech) glue application unit (OPTIONAL)

• Automatic reel splicer (OPTIONAL)

Output: 220 pcs/min.(depending on the shape, dimensions of the product and wrapping material.)

• Several products with different dimensions can be wrapped (rectangular, square or bar)

• Wrapping application with 2 different variations;

· Two-layered wrapping (inner aluminium foil or wax paper - outer glossy/coated paper)

· Single-layered wrapping (aluminium foil, wax paper or glossy/coated paper)

• Inner wrapping material is aluminum foil: 14-16 microns and outer wrapping material is glossy/coated paper: 60-80 gr/m²

• Photocell system for paper and products

• Servo motor driven wrapping material feeding

• Electronical parts used on the machine are branded OMRON, Schneider and SICK

• Pneumatic parts used on the machine are branded FESTO

• True-running radial cams with a hardened process for smooth operation and long durability

• Sequenced aligner and automatic feeding conveyors are suitable for the machine

• Delaying system for inner wrapping material

• Reject device for defective products

• Complete lubrication system

• Full machine control by HMI with color graphic touch screen

• All errors / warnings are visible on the touch screen

• The machine has a motion controller, and it is supported by 10 individual motor (inverter) groups

• Format or style changeover time is 30 minutes

• All format parts are manufactured exclusively for each product. Therefore, the machine does not require any further adjustments after the changeover

• CE certification

• Maintenance is easy for all operators

• Easily accessible parts

• Meets all hygienic requirements

• Automatic feeding conveyor (OPTIONAL)

• (Robatech) glue application unit (OPTIONAL)

• Automatic reel splicer (OPTIONAL)